Unlocking the Cold Chain: The Critical Role of Transportation and Storage in Maintaining Food Safety

Food safety is a critical concern for everyone, from the farmer who grows the food to the consumer who eats it. One of the most vital aspects of ensuring food safety is proper transportation and storage, often referred to as the cold chain. This blog post will explore the importance of the cold chain and how food safety software can enhance its efficiency and effectiveness.

What is the Cold Chain?

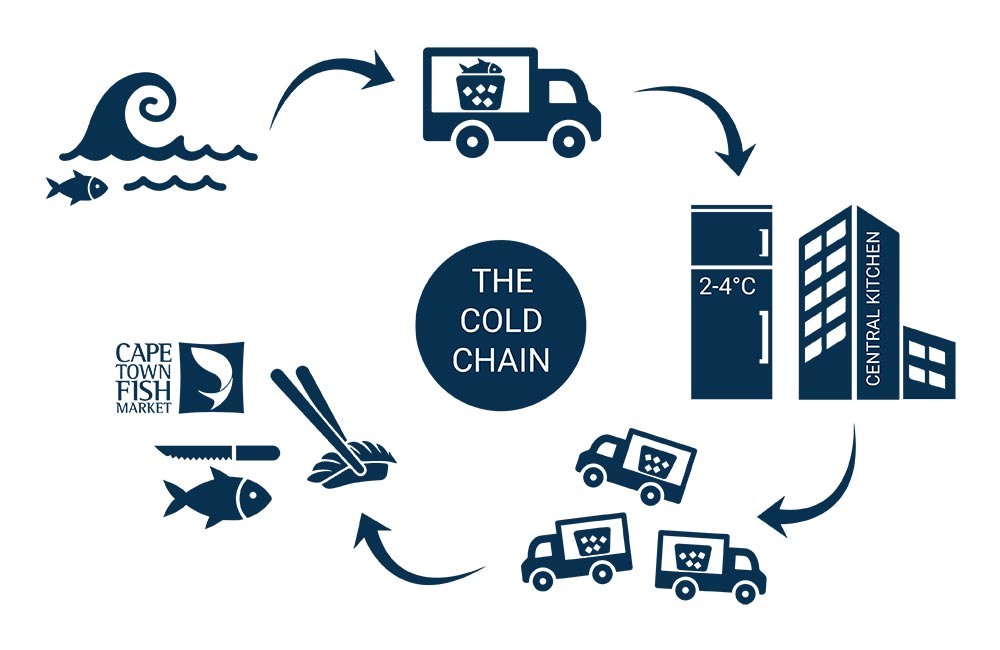

The cold chain refers to the process of managing the temperature of perishable products, such as food, from production to consumption. This process includes all stages of the food supply chain, including harvesting, processing, packing, storing, transporting, and selling.

Maintaining an uninterrupted cold chain is crucial to prevent the growth of harmful bacteria and other pathogens that can cause foodborne illnesses. Any break in the cold chain can result in increased risk and potential harm to consumers.

The Role of Transportation and Storage in the Cold Chain

Transportation and storage play a significant role in maintaining the cold chain. During transportation, it's essential to maintain the right temperature and humidity levels, ensure proper ventilation, and avoid cross-contamination. All these factors can significantly impact the quality and safety of the food.

Storage is equally important. Whether it's a warehouse or a retail store, the storage facility must have the necessary equipment to control temperature and humidity. Additionally, the food should be stored properly to avoid cross-contamination and ensure easy traceability in case of a food safety issue.

Leveraging Food Safety Software

In this digital age, technology has become an indispensable tool in enhancing food safety. Food safety software provides an efficient and effective solution to manage the cold chain effectively.

Here are some ways food safety software can improve transportation and storage:

-

Temperature Monitoring: Most food safety software solutions offer real-time temperature monitoring capabilities. This feature allows companies to monitor the temperature of their products during transportation and storage continually. If the temperature goes beyond the safe range, the software sends an alert, allowing for immediate corrective action.

-

Traceability: Food safety software can track and trace the journey of the food product from farm to fork. This capability is crucial in case of a food recall or outbreak of foodborne illness. It enables companies to quickly identify and isolate the affected products, thereby preventing further spread of the issue.

-

Compliance Management: Compliance with food safety regulations is a key concern for companies in the food industry. Food safety software can help manage compliance by keeping track of all relevant documentation, conducting regular audits, and generating reports for regulatory inspections.

-

Training and Education: Some food safety software solutions offer training modules to educate employees about food safety practices. This feature can be particularly useful in ensuring that all employees understand the importance of maintaining the cold chain and know how to do it correctly.

In summary, the cold chain, involving proper transportation and storage, is a critical element in ensuring food safety. With the help of food safety software, companies can efficiently manage the cold chain, comply with regulations, and ultimately safeguard the health of consumers. By investing in such technology, businesses within the food industry can not only increase their efficiency but also strengthen their reputation for quality and safety among consumers.